NOFLEXN - Life On AIr

We had the special opportunity to take a long-time clients dream and make it a reality. We spent countless hours perfecting every point of this install and making every detail count!

The Vision

Our client, an enthusiast with a deep love for unique and personalized cars, came to us with a clear vision. They wanted their Veloster N to stand out, not just in performance but in aesthetics. We started by stripping down the suspension, readying it for the installation of our custom-fitted air suspension system.

Braided Lines with Precision

The next step was to fabricate the air lines. Regular rubber hoses wouldn’t suffice; we needed something that could handle the pressure while adding to the car’s aesthetic appeal. We opted for custom braided lines, each one meticulously measured and cut to fit the Veloster N perfectly.

Assembling with Love and Time

With all the components ready, the real art began. Installing the air suspension system required more than just mechanical know-how; it required passion and an eye for detail. Every bracket was custom-made, every bolt tightened with care. We routed the air lines through the chassis, ensuring they were both protected and aesthetically pleasing.

The Result

After weeks of meticulous work, the Veloster N rolled out of our workshop, transformed. With the press of a button, the car could now lower itself gracefully, hugging the road in a way that turned heads and drew admiration. The custom braided lines and leather-wrapped compressor were more than just functional components; they were a testament to the love and time invested in this project.

Our client’s reaction made it all worthwhile. They knew they had something truly special, a Veloster N that was a reflection of their personality and our dedication to the craft. This project wasn’t just about bagging a car; it was about creating a masterpiece, one that blended performance, aesthetics, and passion into a rolling work of art.

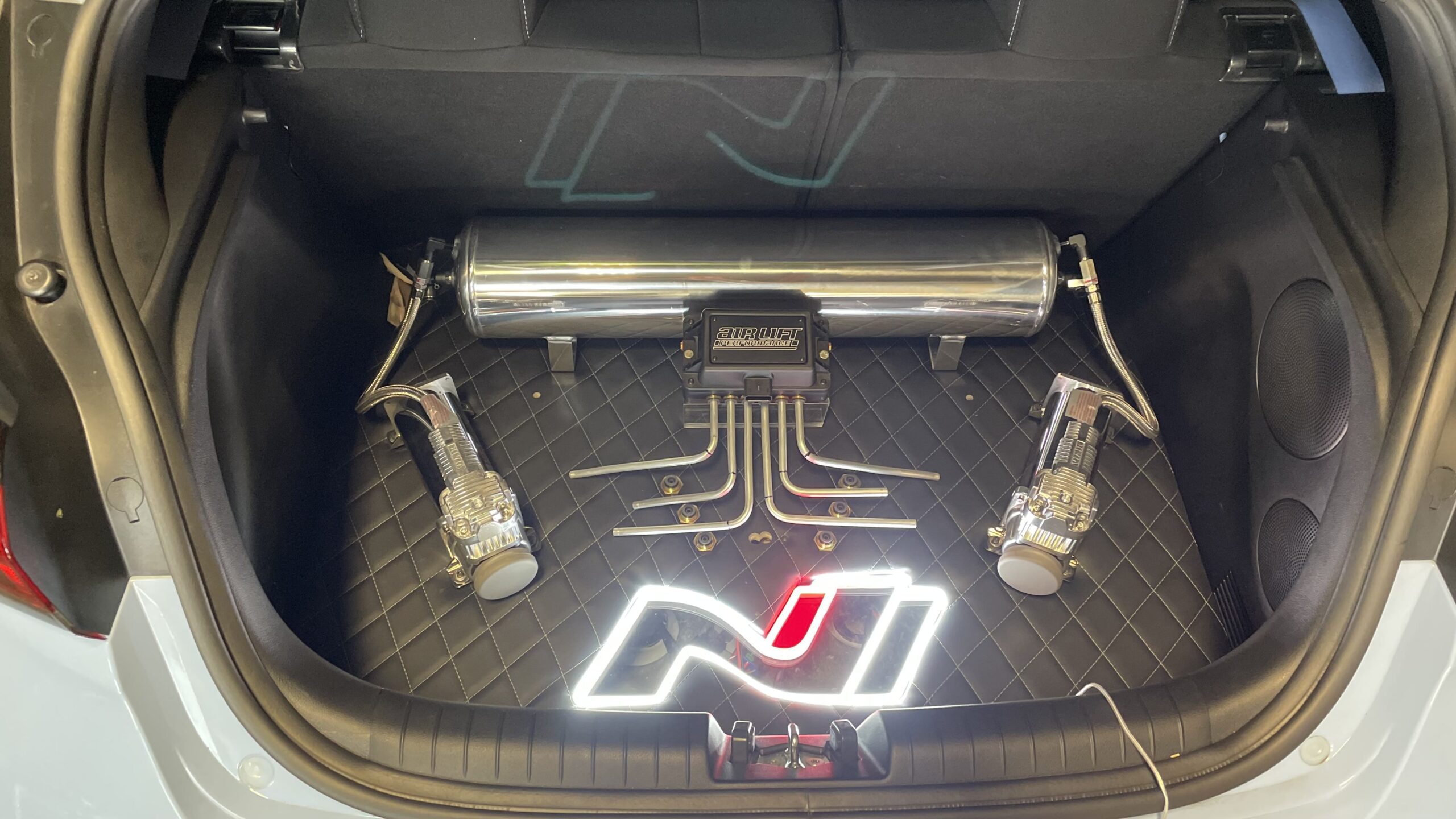

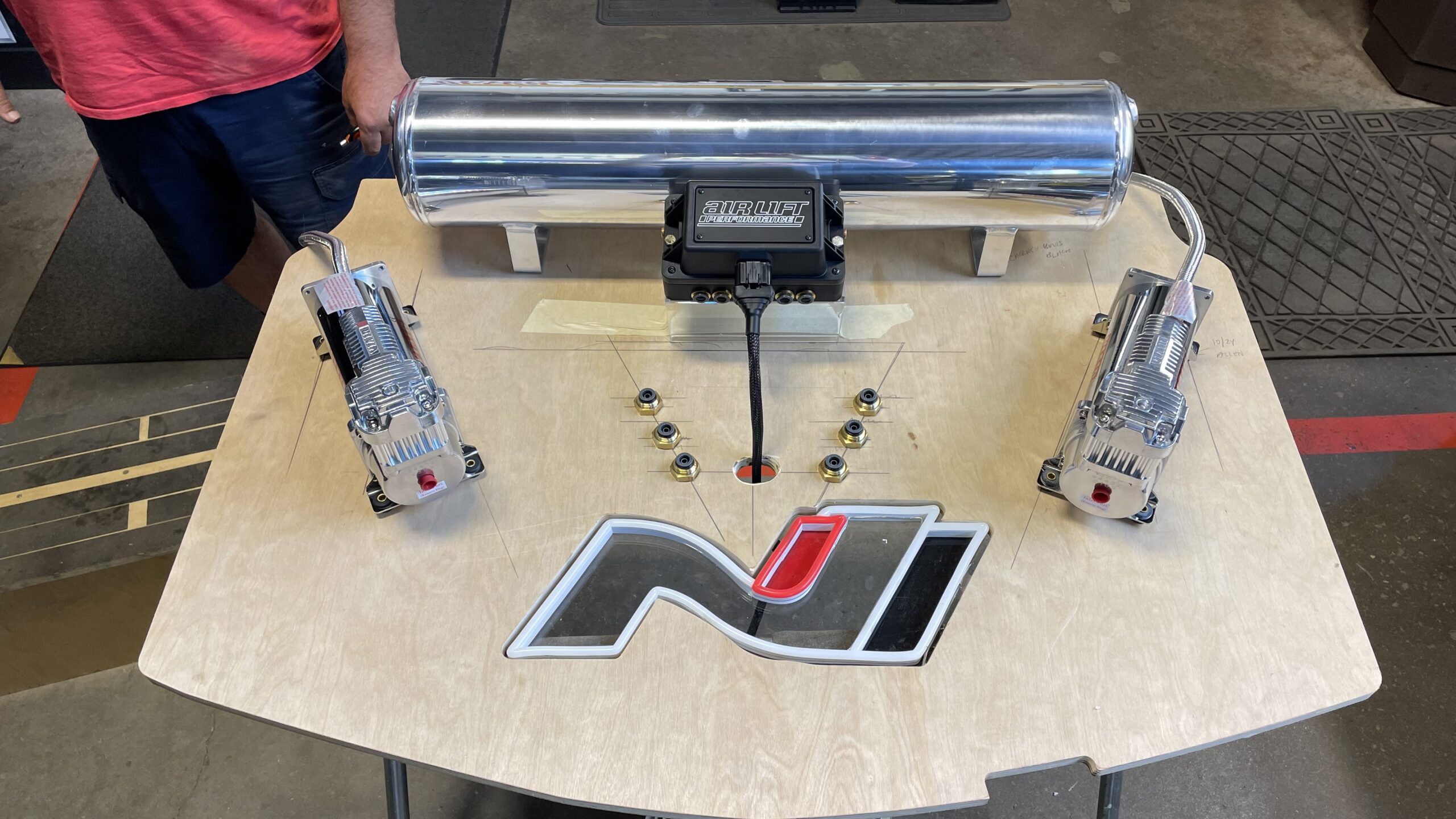

Behind The Scenes

Here you can see a few photos of the air suspension trunk setup as a Work-In-Progress. We took time and care with every detail of this build. Every component choice and design decision carries a thoughtful consideration for performance, serviceability and longevity. We discussed a few different ideas to really make the hardline layout pop! After multiple revisions and conversations we came to a final decision! For this design we had to measure the lines with great precision and accuracy to get the fit just right. This was pretty tough but it worked out well! It took a lot of patience and elbow grease. The results speak for themselves and you can see that the lines came out great! We also chose to integrate an LED backlit Hyundai N logo to really tie the entire project together in a way that pays tribute to the lineage that the Hyundai N-Cars are creating!